Tire’s Home Can Be Fun For Anyone

Table of ContentsThe Greatest Guide To Wheel Store Near MeIndicators on Tire Repair Near Me You Should KnowAll About Tire Replacement

8. Utilizing a versatile knife, reduced the plug on the within of the tire 1/8-inch over the innerliner. Wheel Store Near Me. Take care not to extend the plug when reducing. 9. Making certain the grain arrows of the fixing device are directing to the beads, center the proper dimension repair service system over the injury. Use a tire crayon and also detail an area -inch larger than the fixing device. 10. Use a low-speed buffer (max. 5,000 rpm) and a buffing rasp to rub the plug as well as the laid out innerliner location. BEWARE NOT TO BUFF THROUGH THE INNERLINER. 11. Make use of a vacuum cleaner to totally eliminate the buffing dust.

Apply a light coat of cleaner fluid to the buffed area, scrape clean and allow to completely dry. 13. Use an also layer of self-vulcanizing concrete to the whole buffed location. Permit concrete to dry up until tacky. Never use impact clothes dryers, pressed air or warmth lights to promote drying out. Drying out time is impacted by temperature as well as humidity. 14. When concrete is completely dry, partly eliminate the poly backing from the repair unit, leaving just enough to hold the unit. Press the device right into location while eliminating the remainder of the support. 15. Sew the repair work unit vigorously from the facility functioning externally.

Eliminate top cover film. 16. Apply fixing sealer on the overbuff area, and also over the edge of the repair work system. 17. Apply bead sealant to the bead of the tire before rising cost of living to assist avoid air loss around the bead. (NOT NECESSARYFORTRUCK TIRES.) 18. After pumping up, reduce the plug stem flush with the outside step location. The tire is now all set to be returned to solution. Click on these web links to download and install a complete poster version of this illustrated two-piece tire slit repair service guide, along with one that details single-piece tire puncture repair treatments. After downloading, take the PDF data to a local workplace supply store (Workplace, Max, Staples) or Fed, Ex Kinkos area, where you can publish out a full-color, 1824-inch poster to hang in your tire solution area and/or client waiting area.

Things about Wheel Store Near Me

:max_bytes(150000):strip_icc()/GettyImages-80668563-58c0a4e95f9b58af5ca9d0a4.jpg)

The tire is illegal on U.S - Tire’s Home. freeways. The tire cord or steel belt is exposed, there are flex breaks or extreme sidewall abrasions. There is any type of evidence of a splitting up in the walk location or the sidewall of the tire. There is any kind of evidence to show the tire has been run flat. Do not pump up, considering that inflation might result in serious injury. Demount the tire and also examine for innerliner damages. There are leaks or damages in the shoulder or sidewall areas. Never ever utilize any kind of wheel with a rim that is curved, pitted from deterioration, split or worn. Eliminate rust, dirt and also foreign materials from wheel/rim components.

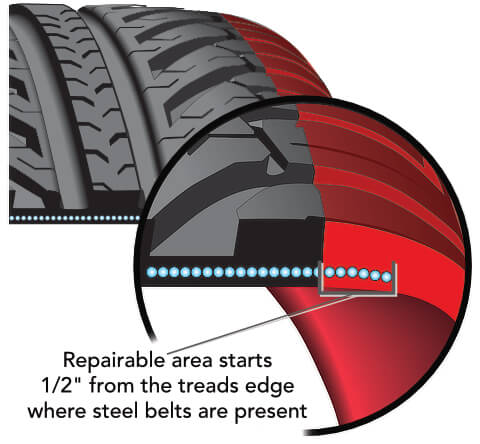

Do not this article overinflate. Check the surface area and the shutoff for the resource of the leak( s) by making use of water, soap service or leakage detector. Locate the injury and also circle with a crayon. Get rid of the valve core to deflate the tire. Demount and also inspect the within of the tire on a well-lighted spreader for innerliner splits, open splices, subjected tire cable or steel belts, damaged grains or bead cables, protrudes or blisters, or other indoor damage. If any type of damages apart from a -inch maximum leak injury in the step is present, do not repair. The last evaluation is your last possibility to see to it a tire leak fixing work was done effectively as well as within sector criteria.

Check every one of your fixings and also revamp, if necessary. After removing and inflating the tire/wheel assembly, check the setting up (tire/wheel/valve) for damages or leak. Pay specific interest to the place of the repair work, the beads and the valve. If the tire remains to lose air, it must be removed again from the wheel for a full re-inspection. The treatments for Web Site fixing a much more major injury on a radial medium truck tire are especially various than when fixing a minor puncture. Section fixings might call for special tools and also repair work materials, consisting of strip gum tissue rubber, an extruder, an area treating press, specifically developed repair devices and also even more.

The Main Principles Of Wheels

While the actions for penetrating an injury angle and also buffing coincide, a grinding (skiving) step must be contributed to remove all damaged cables as well as the length as well as width of the broken area have to be determined to assist in choosing the proper repair system. For crown repair services, skives should be a cupped "Y" kind with a 90-degree skive via the wire belts and also ply. Sewing ought to be done as in a normal repair work before curing the fixing as well as permitting it to cool down. Next, a cleaner liquid should be applied and also the innerliner ought to be scratched clean. When positioning the repair work unit over the injury, center it with the grain arrows aiming directly to the beads.

Do the buffing action, vacuum the dust and also make use of a light layer of rubber cleaner liquid and also a scrape to cleanse the buffed area. Use an also coat of self-vulcanizing concrete to the entire buffed area and allow to completely dry till tacky. Ensure the tire remains in a kicked back setting. Partially get rid of the support from the repair service device, leaving sufficient to hold without touching the back. Apply the spot and press down. After that sew the device, exercising from browse around here the facility. Use as much hand stress as feasible. As a final step, use fixing sealant to the more than buff area as well as over the edges of the fixing unit - Tires.

The coming before post was researched as well as composed using existing industry-approved procedures and material from both the RMA and TIA, and also is NOTintended to be utilized as a substitute for proper tire repair work training. The images as well as added details were provided by Myers Tire Supply/Patch Rubber Co. The procedure revealed below is consistent with those made use of by other significant fixing item makers, yet consult their specific instructions prior to utilizing. This info stands for a consensus of tire industry experts. This short article is indicated for academic objectives as well as those that utilize the methods suggested are entirely responsible for any type of injuries, deaths or losses arising from their application.